Views: 0 Author: Site Editor Publish Time: 2024-01-10 Origin: Site

In the dynamic landscape of industrial machinery, the significance of efficient air handling cannot be overstated. The Side Channel Blower, known by several aliases such as Ring Blower, Regenerative Blower, and Vacuum Pump, plays a pivotal role in various applications, from pneumatic conveying to wastewater treatment.

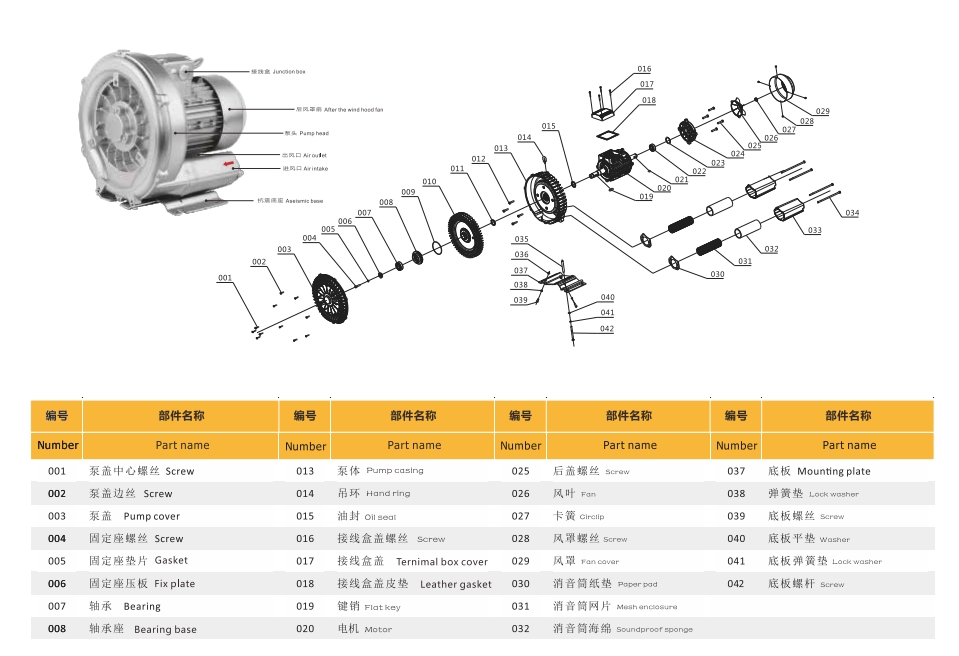

In this comprehensive exploration, we delve into the core components that define the structural prowess of this versatile device, focusing on the critical elements - bearings, motors, and impellers.

At the heart of every high-performance side channel blower lies a robust bearing system. Bearings serve as the backbone, ensuring seamless rotation and reducing friction within the machinery. High-quality, precision bearings not only contribute to the overall efficiency but also significantly extend the operational lifespan of the equipment.

In the realm of side channel blowers, manufacturers often employ state-of-the-art ball bearings or roller bearings. These bearings are strategically positioned to absorb radial and axial loads, fostering stability and reliability in diverse operational conditions. The meticulous selection of bearings is a critical aspect that directly influences the performance and longevity of the equipment.

The driving force behind side channel blowers is the electric motor. Motors serve as the powerhouse, converting electrical energy into mechanical power, propelling the impellers to generate the desired airflow. In this realm, the type and quality of the motor play a pivotal role in determining the overall efficiency and energy consumption of the system.

Efficient side channel blowers often boast high-efficiency electric motors. These motors not only ensure optimal energy utilization but also contribute to the eco-friendliness of the equipment. Variable Frequency Drives (VFDs) integrated into these motors enhance control, allowing for precise adjustments to match the specific operational requirements.

The impeller, or fan wheel, is the component responsible for generating the airflow within side channel blowers. Impellers are meticulously designed to optimize aerodynamics and efficiency. The configuration, size, and material of the impeller are tailored to meet the specific demands of each application.

In the case of side channel blowers, the impeller is a crucial element that defines their performance characteristics. Precision-balanced impellers, often crafted from durable materials like stainless steel or aluminum, ensure smooth and efficient airflow. The intricacies of impeller design are a testament to the commitment to achieving optimal performance without compromising on durability.

In conclusion, the structural integrity of side channel blowers hinges on the meticulous engineering of their core components. The synergy between precision bearings, high-efficiency motors, and aerodynamically optimized impellers culminates in air-handling systems that excel in performance, reliability, and longevity.

As industries continue to evolve, the demand for advanced air-handling solutions will persist. The mastery of side channel blower structures lies not just in their individual components but in the seamless integration of these components to create a harmonious, high-performance system.