Views: 0 Author: Site Editor Publish Time: 2024-09-18 Origin: Site

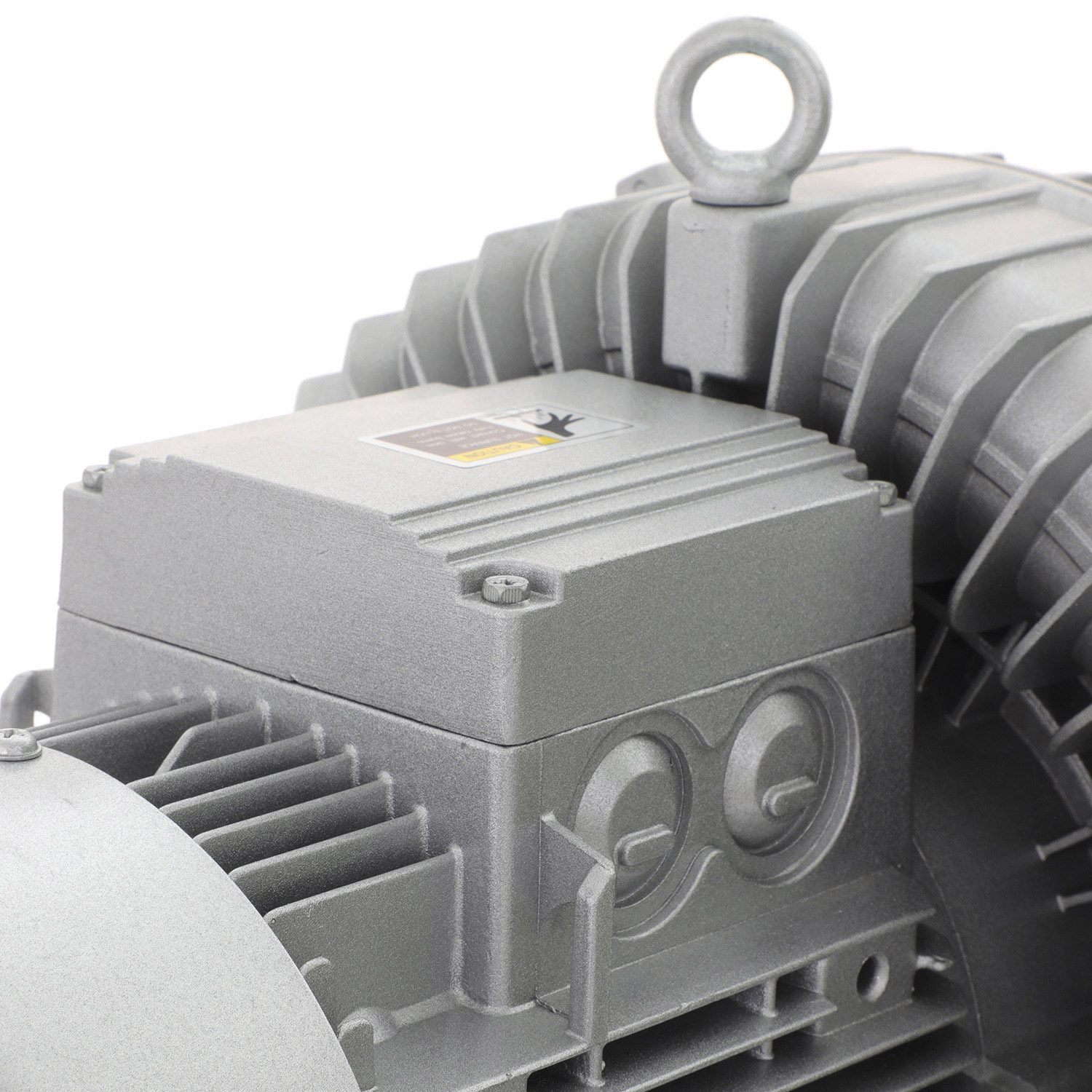

Side channel blowers play a critical role in industrial applications where high-temperature tolerance is required. These devices are often used in environments where conventional blowers may struggle to operate due to the extreme temperatures involved. In this article, we will explore how side channel blowers are designed to handle high-temperature applications, their temperature thresholds, and the technical details that make them indispensable in such environments.

In many industries, processes that involve high temperatures require equipment that can withstand such conditions without breaking down. Applications like plastic manufacturing, chemical processing, and food production often involve temperatures that exceed the operational limits of standard machinery. In these environments, the blower's ability to function without overheating is crucial.

The design and materials used in side channel blowers allow them to operate in a wide range of temperatures. Understanding the typical temperature ranges and how these blowers cope with heat is essential for selecting the right equipment.

Operational Environment Temperature: Side channel blowers are usually designed to function in environments with ambient temperatures ranging between 20°C and 50°C.

Inlet Air Temperature: The allowable air intake temperature for most blowers falls between -20°C and 50°C, ensuring versatility in different environmental conditions.

Bearing Temperature: Standard bearings can handle temperatures from 100°C to 160°C, but for applications requiring higher tolerances, specialized high-temperature bearings can be installed, extending the upper limit to around 180°C.

One of the key factors in maintaining the longevity and efficiency of a side channel blower is how well it manages heat build-up during operation. When running, the temperature of the blower’s pump body can reach anywhere from 60°C to 160°C, depending on the operating conditions, environmental factors, and load. Proper installation and maintenance practices can help ensure that the blower runs within these acceptable limits, preventing premature wear or failure.

During regular operation, side channel blowers experience a temperature rise of 20°C to 60°C, which is considered normal. This increase is largely a result of friction and the compression process. Selecting the right blower model and ensuring adequate ventilation are critical to managing this temperature rise, especially in high-temperature applications.

One of the most critical components in any blower subjected to high temperatures is the bearing system. Bearings in standard blowers are rated to handle up to 160°C, but specialized high-temperature bearings can push this limit up to 180°C. These bearings are made from advanced materials that can resist thermal expansion and maintain their shape under extreme heat, ensuring consistent performance even in the most demanding environments.

The materials used in the construction of side channel blowers also play a vital role in their ability to withstand high temperatures. Many high-temperature blowers are made from aluminum alloys or stainless steel, both of which offer excellent resistance to heat. These materials are chosen for their ability to retain structural integrity and avoid warping, even when exposed to prolonged heat.

The use of side channel blowers in high-temperature applications offers increased durability compared to other types of blowers. Their design ensures that key components, like bearings and seals, are protected from the damaging effects of heat, resulting in longer operational life and reduced maintenance costs.

Many side channel blowers are designed to be highly energy-efficient, even when operating in high-temperature environments. Their regenerative design allows for a smooth and continuous airflow, reducing energy consumption while maintaining high performance. This efficiency makes them an excellent choice for industries looking to reduce operational costs without sacrificing performance.

Due to their ability to handle a wide range of temperatures and pressures, side channel blowers are used in various industries, including:

Plastics Manufacturing: Used for drying processes and vacuum formation.

Food Processing: Essential in vacuum sealing, air knives, and drying systems.

Chemical Industry: Utilized in conveying materials and venting toxic gases.

Power Plants: Applied in cooling systems and aeration for wastewater treatment.

Side channel blowers are essential in industries that require machinery to operate reliably under high-temperature conditions. Their robust design, ability to handle significant temperature variations, and energy efficiency make them ideal for applications ranging from plastic manufacturing to chemical processing. By choosing the right side channel blower and ensuring proper maintenance, industries can enjoy durable, efficient, and reliable performance in even the most extreme environments.